Views: 0 Author: Site Editor Publish Time: 2025-10-16 Origin: Site

If you attempt to have glass be cut after it has been tempered, the tempered glass will break immediately. This is because tempered glass holds internal stress, causing it to react instantly to any attempt to alter it. Even a small chip or minor crack can cause the entire glass to shatter. Uneven heating or cooling during the process of having glass be cut adds even more stress, making it nearly impossible to cut tempered glass safely. For this reason, you should always have the glass be cut before the tempering process. While some specialized factories can have tempered glass be cut, they require advanced tools and highly trained professionals to do so.

You cannot cut tempered glass after it is tempered because of stress inside. If you try to cut it, it will break into pieces.

Always cut glass before it goes through the tempering process. This way, you get the right size and shape. You also do not risk breaking the glass.

If you need to change tempered glass, order custom pieces from experts. This helps keep the glass strong and safe.

Ask certified glass experts for help with handling and installing glass. Their skills help you avoid expensive mistakes.

For projects that need easy cutting, use regular annealed glass instead of tempered glass.

You may ask if glass be cut after tempering. Many people in the glass industry wonder about this. The answer is clear. You cannot cut tempered glass safely after it is tempered. Tempered glass gets stronger during tempering. This strength comes from stress inside the glass. These stresses make the glass break quickly if you try to cut or change it.

Glass should be cut before tempering. This is how most glass makers do it. They suggest cutting first because tempered glass cannot be cut again. Cutting first helps you get the right size and shape. You can also finish edges or add holes before the glass gets too strong.

Tip: Always plan your project well. Finish all work like edging or etching before tempering. This stops problems later.

Here are the usual steps before tempering:

The glass is cut to shape with a CNC cutting machine.

Extra glass is taken off by hand.

All work, like edging and etching, is done before tempering.

If you skip these steps and try to cut glass after tempering, you could ruin the whole piece.

Trying to cut tempered glass after tempering breaks the stress inside. This makes the glass shatter into many small pieces. These pieces are not as sharp as regular glass, but they can still hurt you and make a mess.

Breaking the stress causes lots of tiny pieces.

The whole sheet can break at once.

Even a small chip or crack can break the whole piece.

Tempered glass cannot be cut or changed after tempering because it is stronger and more stable. Its features stop any changes, so glass be cut to the right size and shape before tempering. If you need to cut tempered glass, order custom pieces or ask a professional.

Note: Cutting tempered glass after tempering is rare in the glass industry. Most experts do not do it to keep the glass safe and strong.

If you plan ahead and have glass be cut before tempering, you will save money and keep your project going well.

Cutting tempered glass is very hard. You cannot use simple tools at home. You need special machines and expert skills. Most ways to cut tempered glass happen in big factories. These ways are not safe for home projects. You should always ask experts if you need to change tempered glass.

One way to cut tempered glass is by annealing. Annealing means heating the glass in a kiln. This removes the stress inside the glass. The glass turns back into regular glass. After annealing, you can cut, drill, or shape it. This gives you more choices for custom designs. Annealed glass lets you change the size or add holes. The glass will not break as easily. This method needs special tools and careful heat control.

Tip: Annealed glass is easier to cut and shape. It is good for art projects and custom sizes.

Laser cutting and sandblasting are advanced ways to change tempered glass. Laser cutting uses a CO2 laser for very exact cuts. You can cut glass up to 25mm thick with great accuracy. This lets you make detailed shapes and patterns. Sandblasting uses fast particles to mark or shape the glass. Both ways need special machines and safety gear.

Specification | Capability | Application |

|---|---|---|

CO2 Laser Type | Most effective for glass | General cutting operations |

Thickness Range | Up to 25mm | Various applications |

Precision Level | ±0.1mm tolerance | High-precision requirements |

Cutting tempered glass with lasers has many good points. You get exact cuts, fast work, and custom shapes. You also waste less glass and save on work costs. But if you do not cut right, the glass can crack or break. You must set the laser carefully.

Lever is a leader with its glass tempering furnace. This furnace uses strong air flow for top-quality tempered glass. Lever gives you the right machines and skills for safe glass work. You should let experts cut tempered glass to stay safe.

Feature | Annealed Glass | Tempered Glass |

|---|---|---|

Cost | More cost-effective | More expensive |

Cutting Ease | Easy to cut, shape, drill, and polish | Cannot be cut or drilled after tempering |

Safety Risk | High risk of dangerous shattering | Safer breakage pattern (small pieces) |

Applications | Low-cost, customizable projects | Safety-critical applications |

Note: Cutting tempered glass is risky and costs a lot. Always plan your project and ask experts like Lever for help.

If you need to change the size or shape of tempered glass, there are safe choices. These options help you avoid breaking the glass by trying to cut it yourself.

Getting custom cut tempered glass is the best way to get the right size and shape. You can pick the type, thickness, and edge finish before the glass is tempered. This keeps the glass strong and safe. Most companies let you choose clear, low-iron, or frosted glass. You also pick the thickness, edge style, and corner treatments for safety.

Pick the glass type you want.

Give the exact measurements.

Choose the edge finish and corner style.

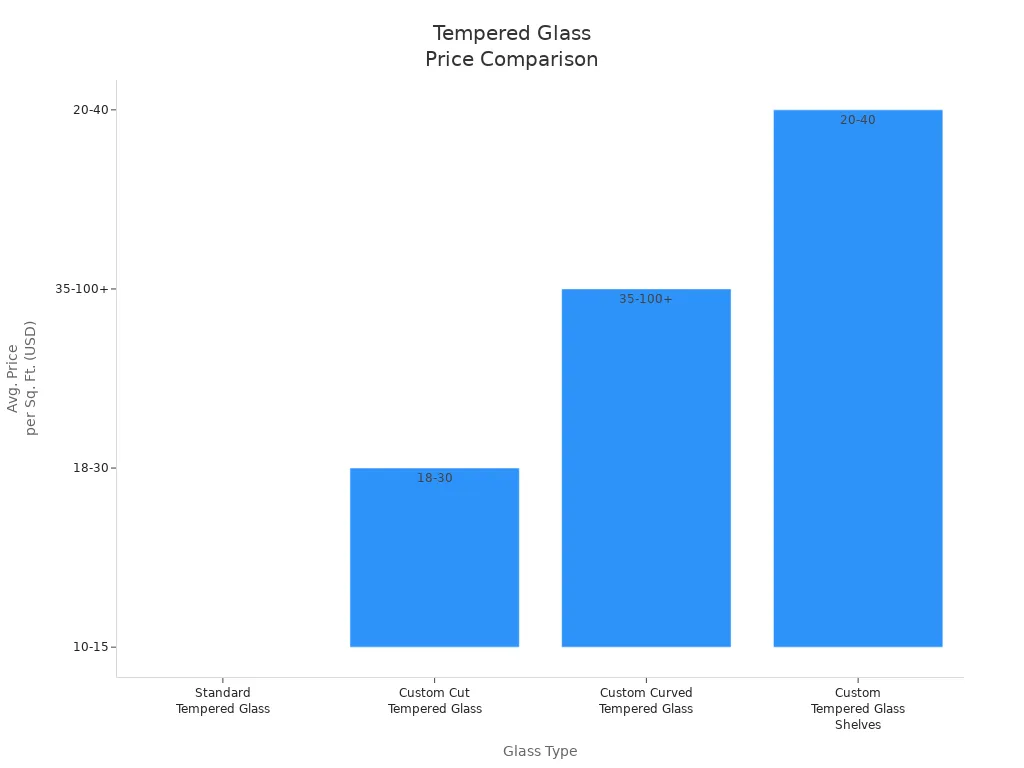

The price of custom cut tempered glass depends on what you pick. Here is a table to show the prices:

Glass Type | Avg. Price per Sq. Ft. |

|---|---|

Standard Tempered Glass | $10 – $15 |

Custom Cut Tempered Glass | $18 – $30 |

Custom Curved Tempered Glass | $35 – $100+ |

Custom Tempered Glass Shelves | $20 – $40 |

Your order will arrive in about 5 to 10 business days. This is faster and safer than trying to change glass at home.

If you are not sure what to do, talk to glass professionals. Certified experts know how to measure, handle, and install glass safely. Look for people with certifications like Certified Glass Installer (CGI) or Certified Glazing Technician (CGT). These experts have lots of training and follow safety rules.

Certification Name | Issuing Organization | Focus Areas |

|---|---|---|

CGI | NGA | Installation, safety |

CGT | NGA | Advanced glazing |

AGMT | FCA International | Architectural glass |

SGCC | SGCC | Safety glazing |

FGIA | FGIA | Fenestration |

Tip: Always check for certifications before you hire someone. This helps you get safe and good results.

If you want glass you can cut at home, try other types. Regular annealed glass is easy to cut with simple tools. Laminated glass is another choice, but it is harder to work with. Professionals should handle laminated glass. Each glass type has different safety and strength features.

Glass Type | Safety Characteristics | Durability Characteristics |

|---|---|---|

Tempered Glass | Shatters into small, blunt pieces | 8-18 times stronger than regular glass |

Laminated Glass | Holds together when broken | Withstands significant force |

Wired Glass | Can break into sharp pieces | Used in fire-rated applications |

Note: Pick the right glass for your project. Tempered glass is best for safety. Annealed glass is good for easy cutting.

You should not try to cut tempered glass after it is tempered. If you do, the glass can break in a dangerous way. Make sure to plan your cuts and pick your glass before tempering. Talking to experts can help you avoid problems and get good results.

When you begin your project, keep these tips in mind:

Tell the fabricator your glass size and thickness.

Work with skilled fabricators for custom glass.

Know where you want holes and edges before tempering.

Picking the right glass early helps you save time, money, and worry.

You cannot cut tempered glass at home with a glass cutter tool. The glass will shatter because it holds strong internal stress. You should always cut glass before tempering.

You should not use a wet saw to cut tempered glass at home. The glass will break into small pieces. Only professionals with special equipment can handle tempered glass safely.

You can cut glass at home if you use regular annealed glass. Use a glass cutter tool for straight cuts. Always wear gloves and safety glasses to protect yourself.

Tempered glass breaks because it has built-in stress. When you try to cut tempered glass at home, the stress releases quickly. This causes the glass to shatter into many pieces.

You cannot cut glass at home after tempering. The glass will shatter. If you need a special size, order custom tempered glass from a professional.